“Vagabond’s” restoration…the story in words and pictures, Part 3 (2025)

Last updated: 22nd December

As winter progressed into 2025, so did work on various aspects of "Vagabond's" restoration, as shown in the following photos taken during the first few weeks of the New Year.

These show continuing work on wing access panels (replacement), baggage door surrounds, wing spars (including rebuild of parts previously removed/damaged) and side windows.

Repairs were also carried out to our hangar following some wind damage and further matting was added around our work area to improve underfoot conditions!

The “Tech Team” didn’t miss a scheduled workday despite frequently inhospitable conditions - a great effort!

As we moved towards spring, work continued in a similar vein, with the team progressing towards the day, hopefully during the coming months (with June’s Air Day at Blackbushe being the target), when “Vagabond’s” main spars were once in place within the fuselage, with the stub wings and main landing gear re-attached.

The next set of pictures show continued progress on window frames, spars, engine nacelles, inner (stub) wings and baggage door frames - this last part bringing the welcome sight (and sound within the hangar!) of a rivet gun in use.

The 6th March saw the arrival back at Blackbushe of "Vagabond's" main landing gear, which has been superbly restored by the apprentices at our supporters Safran Landing Systems.

It was stored away in a newly completed addition to our work area at Blackbushe, which will in due course become our spray shop. For that, thanks were also due to Trustee Paul Nicholls and his Team at JP Building & Design Ltd.

Other work on the aircraft had also continued during the previous weeks, including interior cleaning and further work to repair spars and baggage door areas.

At the end of April, we reached the anniversary of 2 years since the BHT Team had arrived in Bad Voslau to take “Vagabond” apart ready for her road journey back to Blackbushe. We were by now getting closer to the day when some key parts of the aircraft will be joined back together again. In addition, some new areas of work were getting underway.

The pictures below show, in order, the work-in-progress and how far we’d come at that 2 year point….

Main landing gear, immaculately restored by Safran, awaits re-installation

Stub wing spars being readied for re-attachment of engine nacelle

Re-manufactured starboard wing spar awaiting re-positioning back into fuselage

Repairs to baggage hold entrance

Baggage hold cleaned and refurbished

Re-manufactured port wing spar awaiting re-positioning back into fuselage

Newly manufactured trestles awaiting placement of wings for refurbishment

Rudder pedals and other cockpit parts taking shape

Refurbishment of wing fillet panel

More work on window trims - results can be seen above the work area

Undercarriage re-attachment fittings in place within engine nacelle

How "Vagabond" looks exactly 2 years after she left Bad Voslau

The 24th May was a bit of a landmark day, as the first major parts of "Vagabond" to come together again since she arrived back at Blackbushe at the beginning of May '23, the starboard stub wing and fuselage, were joined back together by the Team that morning.

Quite a bit of re-engineering and re-construction had to take place to get us to that point, and we were hopeful that the following week the port stub wing would be re-joined to the fuselage aswell (preparation for that is shown in the last of the photos below).

There was some really great work, ingenuity and improvisation at times by the Team to get us to that point!

As we had hoped, on 28th May, the hard work, ingenuity (and again, sometimes improvisation!) of the Team paid off as "Vagabond's" port stub wing was now also attached, both to the aircraft and also to the other stub wing, through the centre of the aircraft - as shown in the next group of photos below. As previously mentioned, we had set this as a target to be achieved in time for the Airport’s forthcoming Air Day on 14th June, and it was!

The 3rd June was also a busy day at the heritage hangar, as “Vagabond’s” outer wings were relocated onto their newly manufactured trestles in order to make space for another storage container for the Team.

The move of the wings also helped the Team to start the restoration process for them with much better access. Big thanks were due to Recovair Ltd and to Tim their driver for the use of the HIAB truck.

The Air Day itself on 14th June saw much better weather than 2024 and was a big success for both BHT and the Airport. It was great to see so many people coming to look at the great progress we’re making on “Vagabond’s” restoration, and helping with that progress by spending money on our sales stalls, and our Summer Raffle.

Note: There won’t be an Air Day in 2026, due to the much-anticipated building development work that should be well underway on the airfield by then.

Many members of the BHT volunteering Team at the 2025 Air Day

3 weeks on from the Air Day in early July, and routine operations had resumed for the Team, every Wednesday and Saturday. Among the activities underway at the time, as shown in the pictures below, were….

Paint stripping of the outer wings had started, as had restoration work on flaps and ailerons

Work continued on the temporary repairs to the side windows

The stub wings were being prepared for the day when the next part of the structure (engine nacelles) would be re-attached

Wing-to-fuselage fillets were being either restored or re-manufactured and re-fitted. Work also continued on landing gear doors

The restored main landing gear was being re-fitted inside the engine nacelles

Into late Summer, and the (mostly) very good weather had certainly helped our progress. It was also great to see a few new faces joining us over the last few months. The next set of pictures hopefully tell the story of progress on some aspects we’d been working on for a while, and others that were just getting started, as follows.....

1. Rain doesn't stop play, work continues in the dry of the workshop

2. Outer wing flaps under restoration

3. Restored flap section

4. Wing fillet being readied for re-installation

5. Wing paint stripping continues!

6. Replacement spar bolts

7. The newly restored windows get a rain test

8. Cockpit rebuild underway (this was almost completely stripped when we acquired the aircraft).

In mid-September, there was also exciting news that we had been successful in our bid to acquire Vickers Valetta C.2 VX573 from the RAF Museum at Cosford (as covered in more detail in our September general news update - Edition 16, here https://www.blackbusheheritagetrust.com/news).

The hope is that this aircraft, as seen below in earlier times and which is in very good condition, will arrive at Blackbushe in the Spring of 2026. More details will be communicated about the associated involvement of the “Tech Team” as plans come together!

We’re now well into the autumn (early November at the time of writing), and work has continued on many familiar aspects of the Team’s work, with some of the more recently commenced tasks starting to take shape. In terms of things we’d been working on for a while, there was:

Continued engine nacelle repairs

Wing fillets now being fitted and looking good

Continued landing gear door work

Continued paint stripping, now on the horizontal stabilisers

Etch prime coating being applied to the outer wings

Aileron removal for refurbishment

Baggage door frame repairs continued

Among the more recently commenced tasks were:

Templates being made to repair the join to the rear fuselage

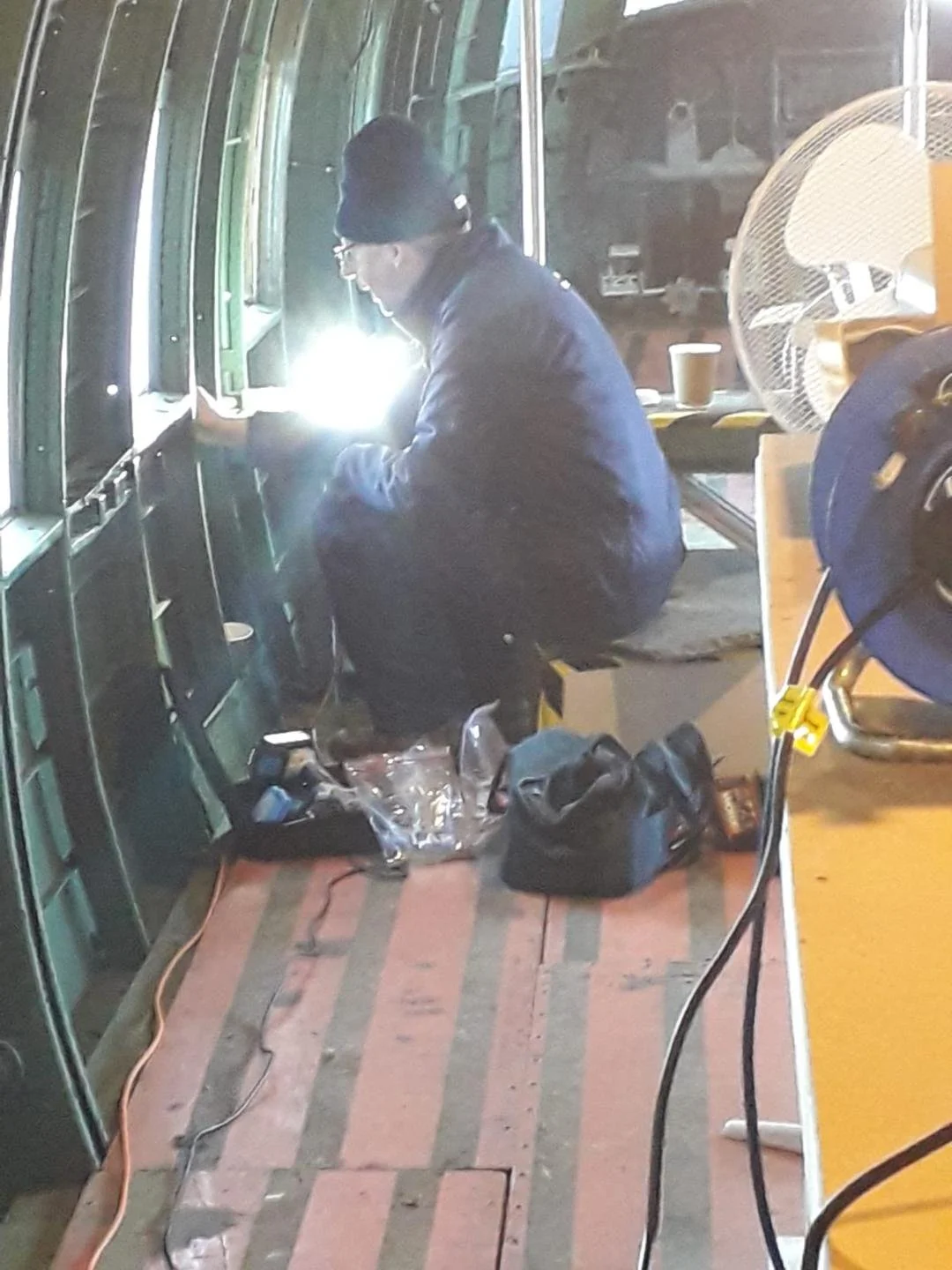

Rear fuselage renovation and preparatory work in progress

A work bench has been constructed for use inside the fuselage

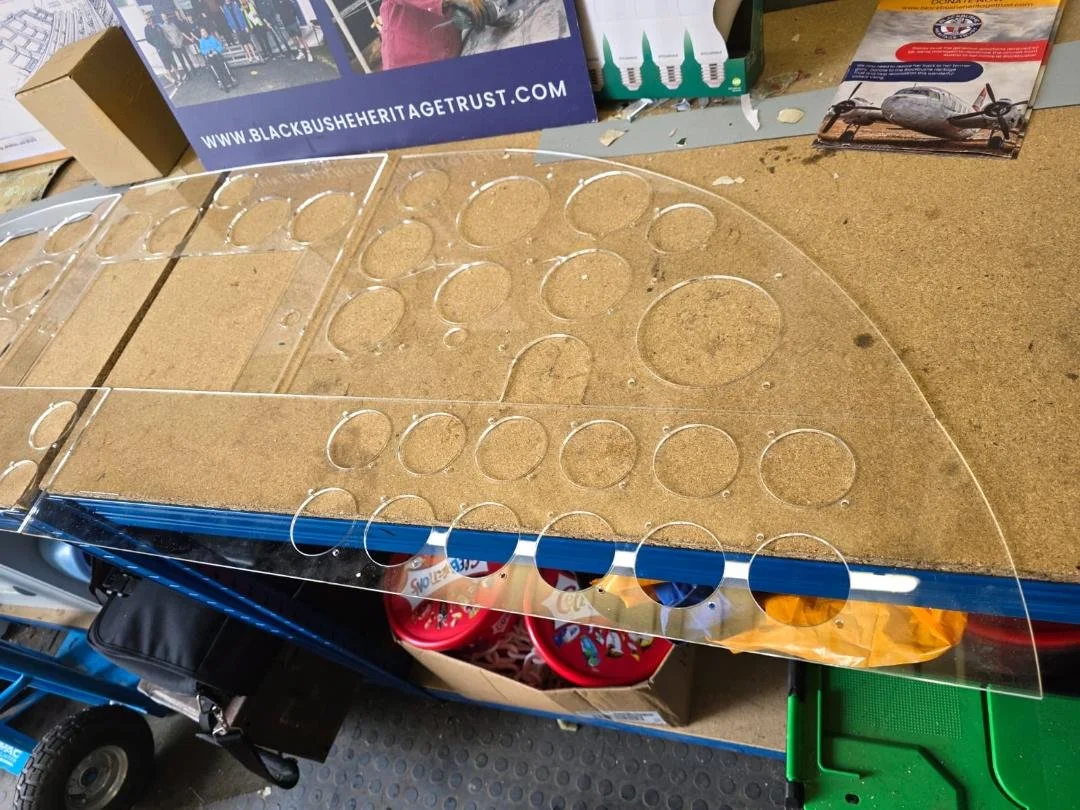

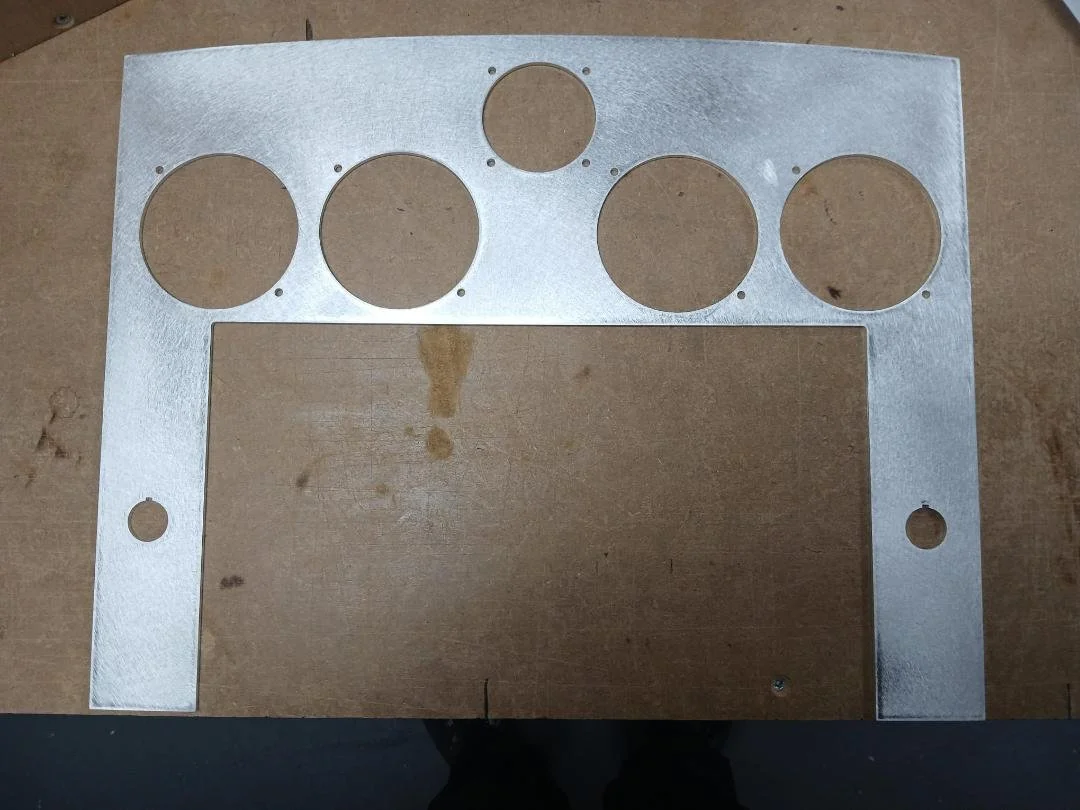

Acrylic test pieces started for instrument panel rebuild and instruments tested for fit. Once all panels are cut they will be test fitted to “Vagabond” for any final corrections that may be necessary

A new gantry has been acquired and assembled. The first use for this will be when the engine nacelles and engines are re-mounted

The next update comes to you in mid-November and some specific areas of work are shown in the latest photos below:

Engine nacelle under refurbishment having been stripped of paint.

Work continues outside on the outer horizontal stabilisers and wings. The 3rd picture shows the port aileron receiving attention.

Work continues in the rear fuselage, an area that needed a lot of attention. We won’t be able to re-attach the rear (tail-cone) of the fuselage until we are able to move it forward further out of the hangar. In turn, that cannot happen until the engine nacelles and main landing gear are re-attached.

Engine nacelle detailed repair is progressing

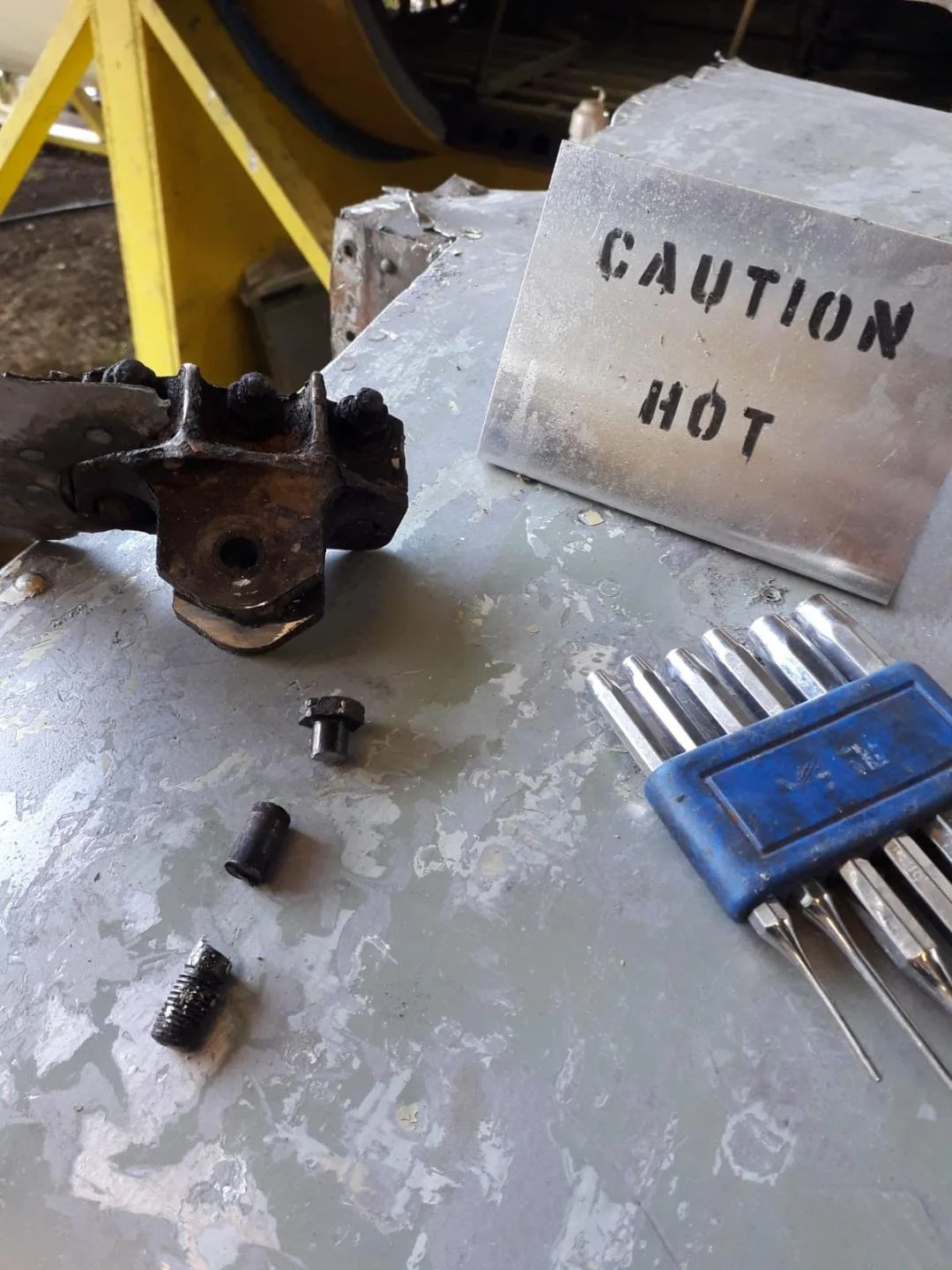

The last 2 pictures show a horizontal stabiliser stub under restoration, and the many stages of the process of removing a bolt - lubrication, torqueing, heating, levering and pressing - our Team have ways of making things happen!

On Monday 10th November, some members of the “Tech” Team were at RAF Cosford to carry out an assessment on our recently-acquired Valetta VX573, as the start of preparations to bring her to Blackbushe during the Spring of 2026 get underway.

Below are some photos of the outside and inside of the aircraft showing just how complete and in good condition she is!

Despite very cold and wintry weather (especially on Wednesday 19th November), the Team have been out braving the elements and continuing work on familiar parts of the aircraft….

aileron and wing tip removal for repair

horizontal stabilizer stub renovation

engine nacelle repairs

priming of repair parts for the above in our paint shop

paint stripping of wings and horizontal stabilisers continues in all weathers!

Another area where work has been gathering pace is on the cockpit rebuild - if you’ve followed our story you’ll know that when we acquired “Vagabond” the cockpit had been almost completely stripped. In 2024 we were very lucky to be able to acquire a large percentage of the original cockpit instruments, and over time others are being gathered, thanks to cockpit rebuild lead Rich and other volunteers who are keeping their eyes open!

The pictures below show acrylic templates of various cockpit instrument panels that have been fabricated for us. These are being used for trial fits, before aluminium versions that will be installed to the aircraft are manufactured.

Moving into late November, the Team were engaged in some removals work, as a couple of engines - a Bristol Hercules (as used by the Vickers Viking) and a Rolls-Royce Dart turboprop, both of which are on loan to us from Rolls-Royce - were moved out of one of our containers at Blackbushe and transported by road to The Chetton Heritage Museum in Bridgenorth, where thanks to Julian Millington they will receive some “TLC” and be stored in a better environment than we can provide for the winter. We’re very grateful to them for their assistance. The pictures below show the moves underway and the engines being loaded and leaving Blackbushe on 30th November.

In early December, work continued on familiar areas such as wing fillets, horizontal stabilisers, outer wings, ailerons and now also the fin, rudder and wing tips.

Another part of the aircraft that we started to work on were the propellers, with the initial tasks being to dismantle them so that the sawn-off propellor stubs (2 blades on each 4-blade propeller) can be welded back together. To recount the story, this was because they unfortunately had to be sawn to fit on the truck for transportation back from Austria in 2023!

Some photos illustrating various stages of this, and some of the other work are shown below:

Wing fillet repair work - outside and inside of the fuselage

Wing tip restoration underway

Horizontal stabiliser ready for priming

Work also commenced on the rudder (pictures 5 and 6)

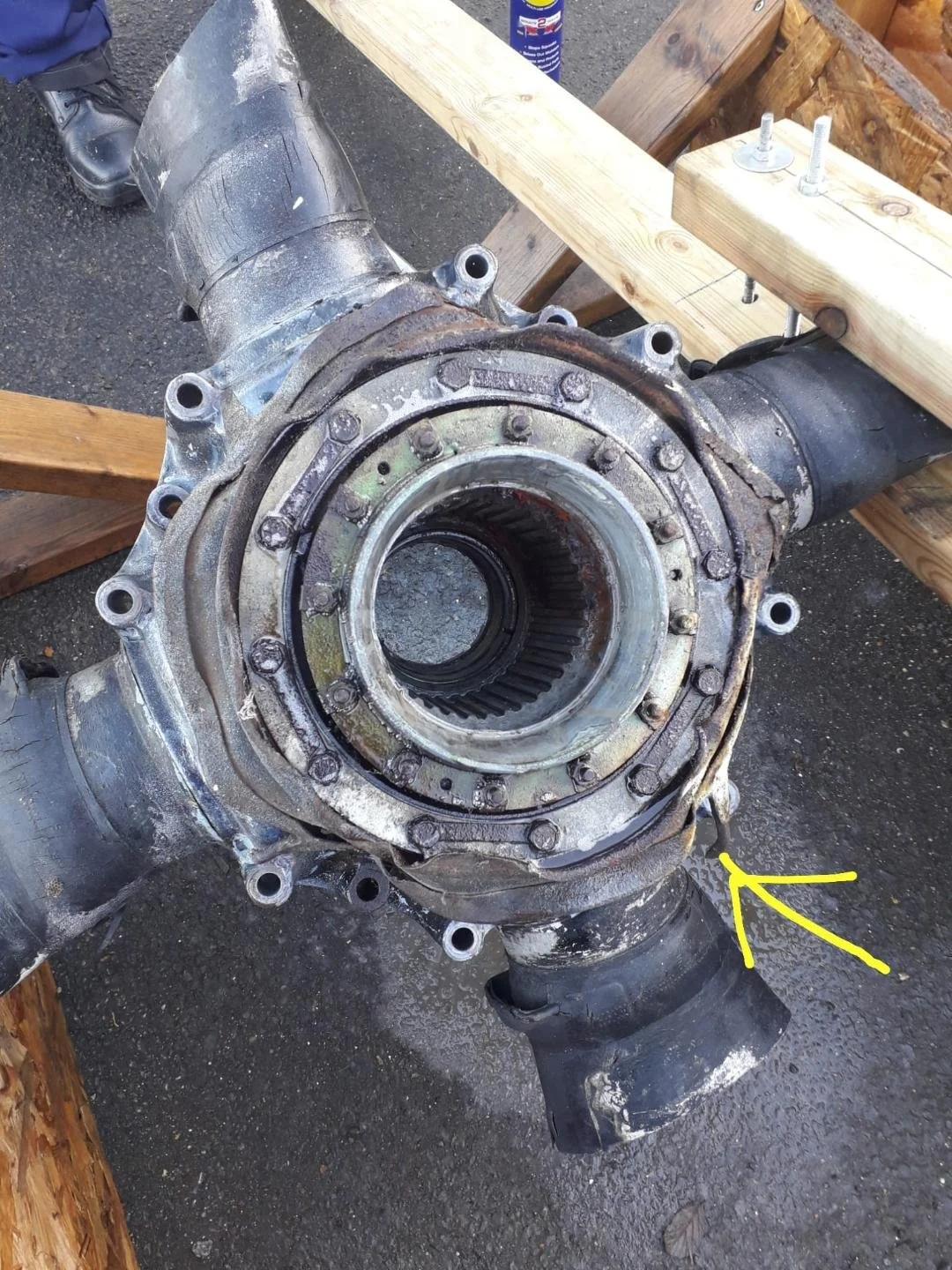

Disassembly work started on the propellers, picture 8 showing the de-icing ring (pointed out by the yellow arrow) and picture 9 showing it removed for restoration.

The final picture shows sheet metal fabrication underway in our workshop container (which is not heated!)

On Saturday 6th December, around a dozen of the Team gathered for their routine Saturday morning of work, with some festive spirit in evidence! Work continued on similar themes, of note being more work on propeller dismantling and also a trial fit of some cockpit instruments to the acrylic instrument panel templates, which we are very grateful to Max Blood for designing and providing. The day’s activities are illustrated in the pictures below:

Work on port aileron and starboard aileron removed for restoration

Work on fin and rudder (pictures 3 and 4)

Damaged rudder skin removed (picture 5)

Pictures 6, 7 and 8 in sequence show the propeller lock ring removed to allow in turn the barrel retaining plate to be removed followed by the clearance of the inboard barrel.

The forward fuselage was washed down

The final picture shows a trial fit of cockpit instruments to an acyrilic template as described above.

At the end of the morning’s work the Team gathered to send some Christmas cheer!

Merry Christmas, from the BHT Tech Team! They’ll be back again a few more times before we finally close out the year.

We’re a few days from Christmas now and the Team have gathered a few more times in the run-up with further activity to report, as follows….

On Wednesday 10th December, the Team temporarily secured the port engine nacelle in place. This was to ensure “Vagabond” was looking at her best for a visit from BBC South on the 11th, when BHT also hosted a well-attended talk by WW2 “Pathfinder” and Mosquito pilot Flt Lt (Ret’d) Colin Bell. We expect the article that was filmed by the BBC to be shown early in the New Year (date tbc at time of writing).

“Vagabond” with port engine nacelle temporarily installed on 10th December

Work continued right up to Saturday 20th December, with the pictures below illustrating the latest activity….

work on the starboard nacelle refurbishment continued.

the second picture shows inside the port nacelle before it was again removed, illustrating the dihedral angle of the main spar as it passes through. The top of the refurbished landing gear can also be seen.

the port nacelle was re-removed for further work and final re-installation at a later date

work to paint strip the fin led to this very interesting “reveal” of former Autair colours and the aircraft registration

after some persistance, the sawn-off propeller stubs were removed

a complete propeller blade was also freed (with neighbouring booted foot for scale)

work to clean and refurbish flaps continued

in preparation for more winter weather, some new flooring was laid around the aircraft

great progress is being made with cockpit instruments, a trial fit into one of the acrylic templates provided by Max Blood was made of the full co-pilot blind-flying panel

the first permanent panel in aluminium has also been cut

That’s all for 2025. We’ll be back with a new blog in 2026!