“Vagabond’s” restoration, Part 4….into 2026

Latest update: 12th February

2026 started in a fairly wintry way at Blackbushe, including a light fall of snow on 6th January, as captured by our volunteer James….

Undaunted, our “Tech Team” had already returned to carry on where 2025 left off and by the time of writing (8th Jan) had completed a couple of sessions, with the focus of their efforts detailed in the words and pictures (credit: Phil) below….

Work on what will be one of the team’s major tasks for 2026, namely the repair of the rear fuselage, continued. A lot of re-fabrication of various parts is going to be needed as this progresses.

The painting with primer of flaps and other parts (including carburettor intake ducts, as shown in the 3rd picture) continued, with our “spray shop” being warmed-up to aid the hanging-out-to-dry process (4th picture)

Propeller stubs and sawn blades were cleaned and matched

Trial fit of instruments to the acrylic templates continued

The fin was moved inside where some heat was applied to aid the stripping process

Work continued on wingtips, ailerons and wing fillets

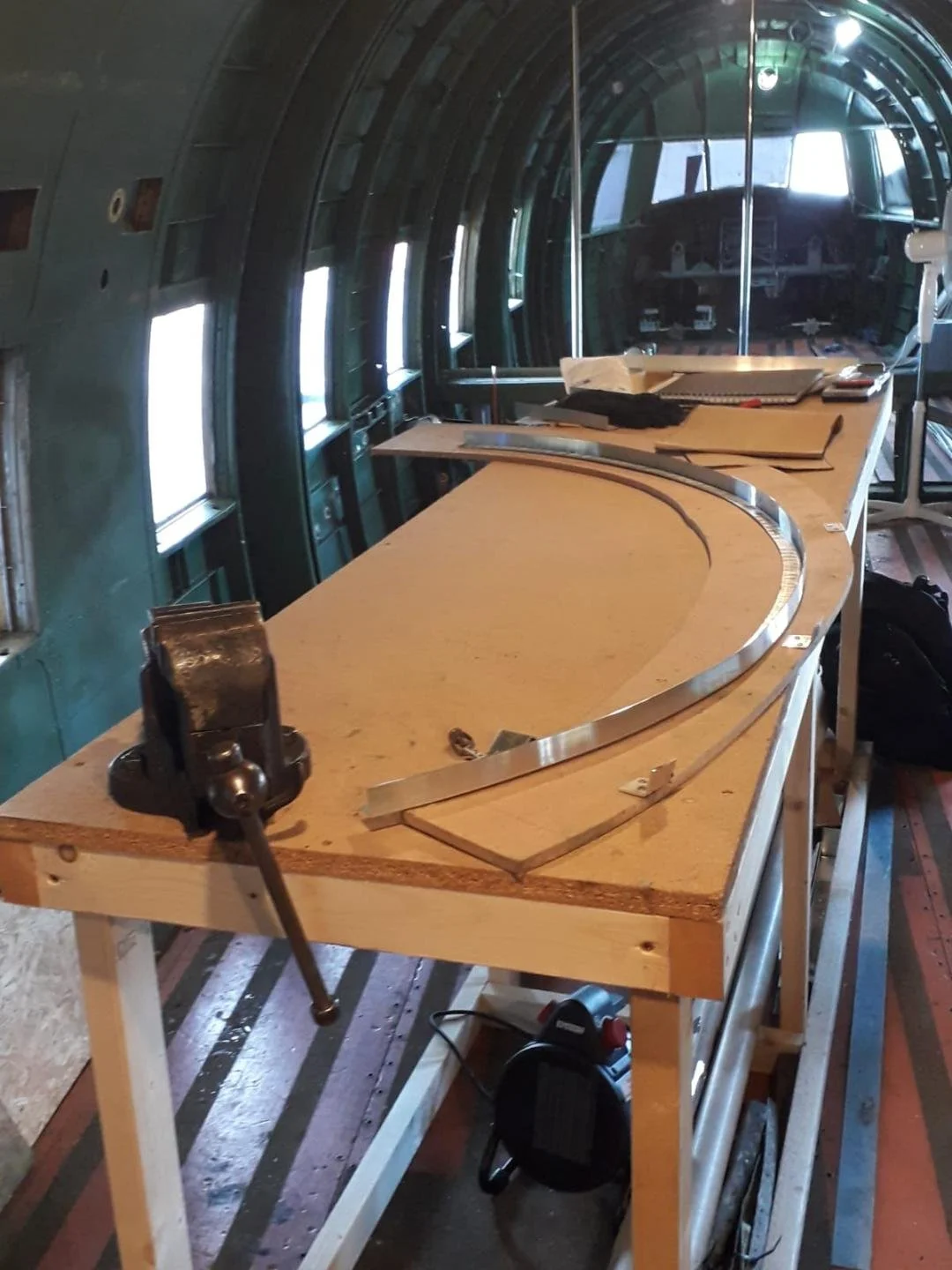

The additonal workshop now in place inside the fuselage saw rib-forming underway, another part of the rear fuselage rebuild

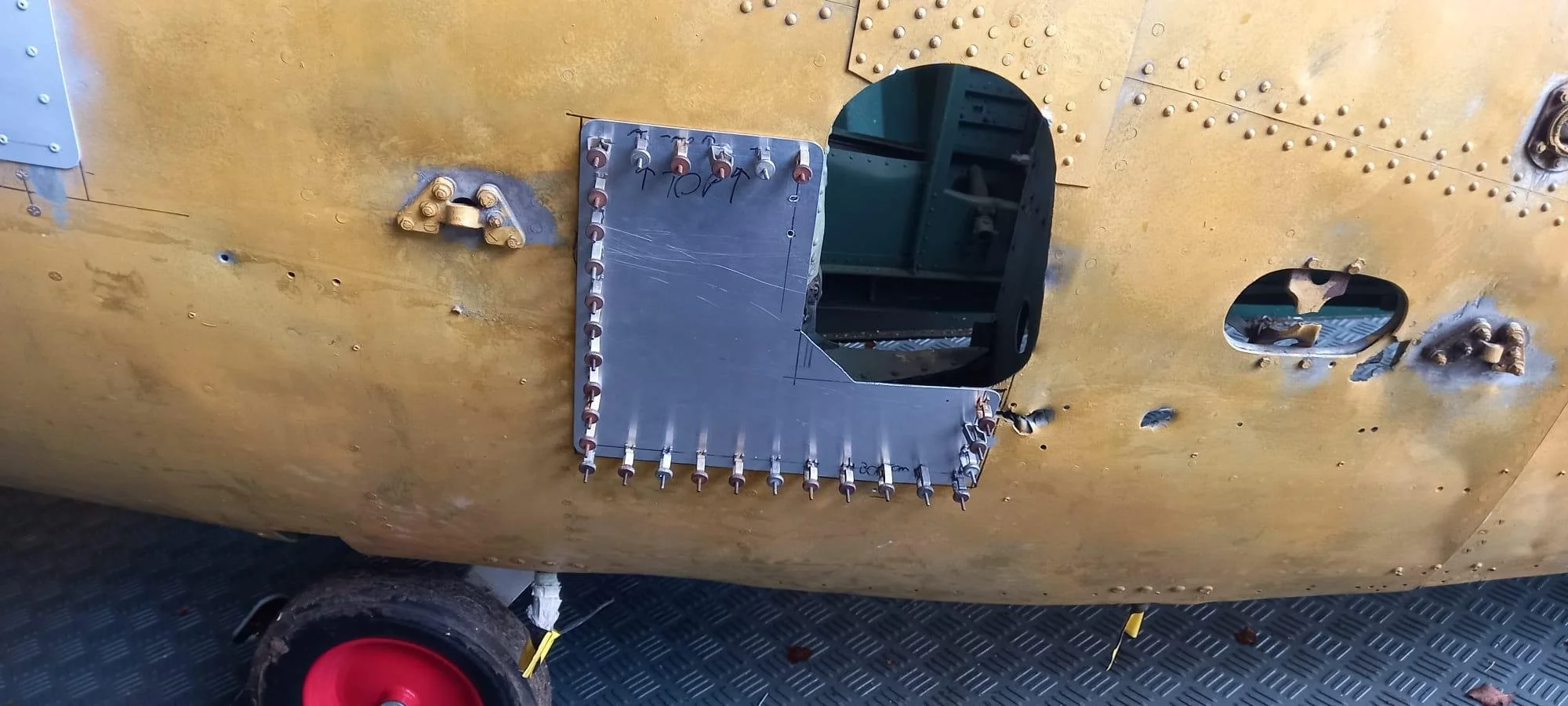

Finally, nacelle repairs saw some end results with the starboard nacelle now completed (last 3 pictures)

Further into the month, this update being added on 22nd January, work continued, often in less than ideal (wet!) conditions, with similar continuing themes to the types of work being carried out. There’s more illustration of these activities in the following photos, as described below (photo credits: volunteers Phil and Nathaniel)….

Outside and inside, work progressed on the wings, and the vertical and horizontal stabilisers. The 4th picture below shows work on one of the horizontal stabiliser stubs.

The engine nacelles continued to receive attention. There’s been a lot of patching-up, which is now near to completion. The 2nd and 3rd pictures below show damage and how it’s been repaired, and the 4th work on a nacelle upper access panel.

As mentioned at the start of this 2026 blog, the rear fuselage is one of our focus areas of work for the coming year. The first photo below shows a rib trial fit and the second repair of the area where eventually the rear section will be re-fitted….

An elevator tip is shown below, firstly in dented condition, and in the second picture slightly less so!

Finally for this update, wing fillets, which were either in a poor condition or needed complete re-fabrication after the aircraft was dismantled in Bad Voslau, continue to receive attention…

Into February (this update being added on the 12th) and despite the wettest start to a year that most of us can remember, work continues on a lot of familiar areas of the aircraft, along with some new ones as the scope of the team’s work expands and some areas (nacelles being a good example) are nearer completion.

Some examples of parts of the aircraft now receiving more attention are the engine cowlings, and a jig that has been constructed to mount the fin vertically for restoration….

As work continued on areas that have been in progress for some time, interesting details become more visible, such as the internal detail of the ailerons (which have now both been removed from the outer wings for restoration) and the rudder. The pictures below show the starboard aileron taken inside for repair and the skinless rudder showing de-icing pipes that would normally be hidden from view, followed by a more general view of the stripped-down rudder….

Other areas where work has continued include the following, as shown in the pictures below:

Nacelles, with replacement panels being added

The wing fillets see continued work

The same can be said of the horizontal stabiliser stubs, with skins being removed for refurbishment and to enable interior work

The rear fuselage, specifically forming a rib section in this case

We’ve also been continuing our collaboration with our friends who are restoring the other UK-based Viking, “Vagrant”, at Brooklands Museum. They’ve been to Blackbushe a few times to make use of our facilties, specifically our “spray shop” where they prepped and painted some interior ceiling duct sections for their aircraft, as shown below….

Finally for this update, a flashback 2 years to show how the main landing gear looked at the time, and how it looks more recently, having been fully refurbished by Safran Aerospace and installed into the nacelles. Just one example of the great progress the Team are making….